Quality Inspection Equipment

-

Magnetic Particle Flaw Detection Test With Handy Magna and Black Light

This test detects even minute flaws in detailed parts caused by the forging process by using florescent magnetic particles. -

Brinell Hardness Testing Machine (Hydraulic)

This is to check the hardness of forged products that have been heat-treated in-house or at partner companies, and to guarantee the required hardness, which varies for each product. -

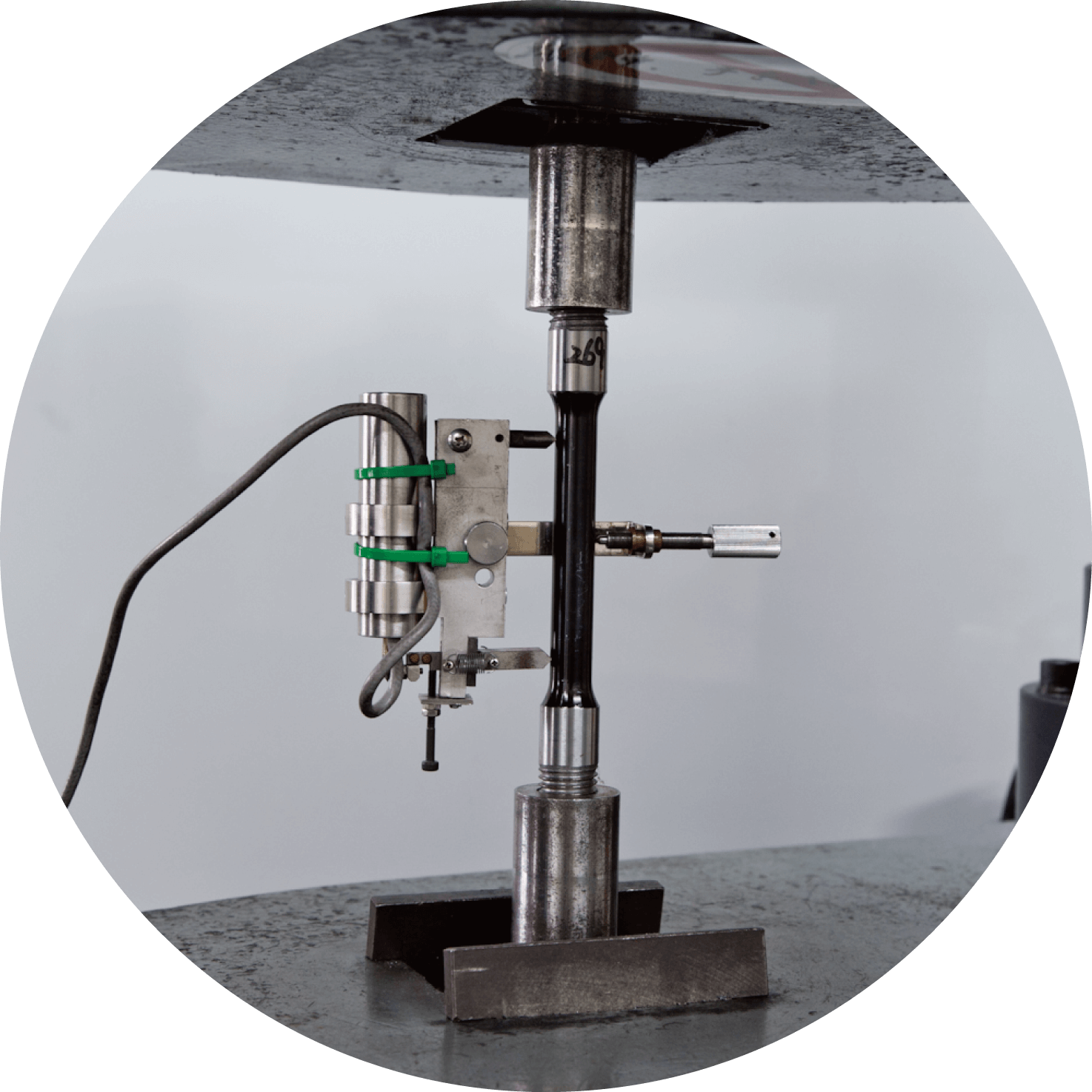

Tensile Testing Machine (Amsler-type Rigid-frame Negative-pressure)

The mechanical properties of the forgings that we manufacture are checked in-house to assure the required quality. -

Ultrasonic Optical Flaw Detection Test

We can also perform ultrasonic optical flaw detection tests upon request, as well as magnetic particle flaw detection tests. -

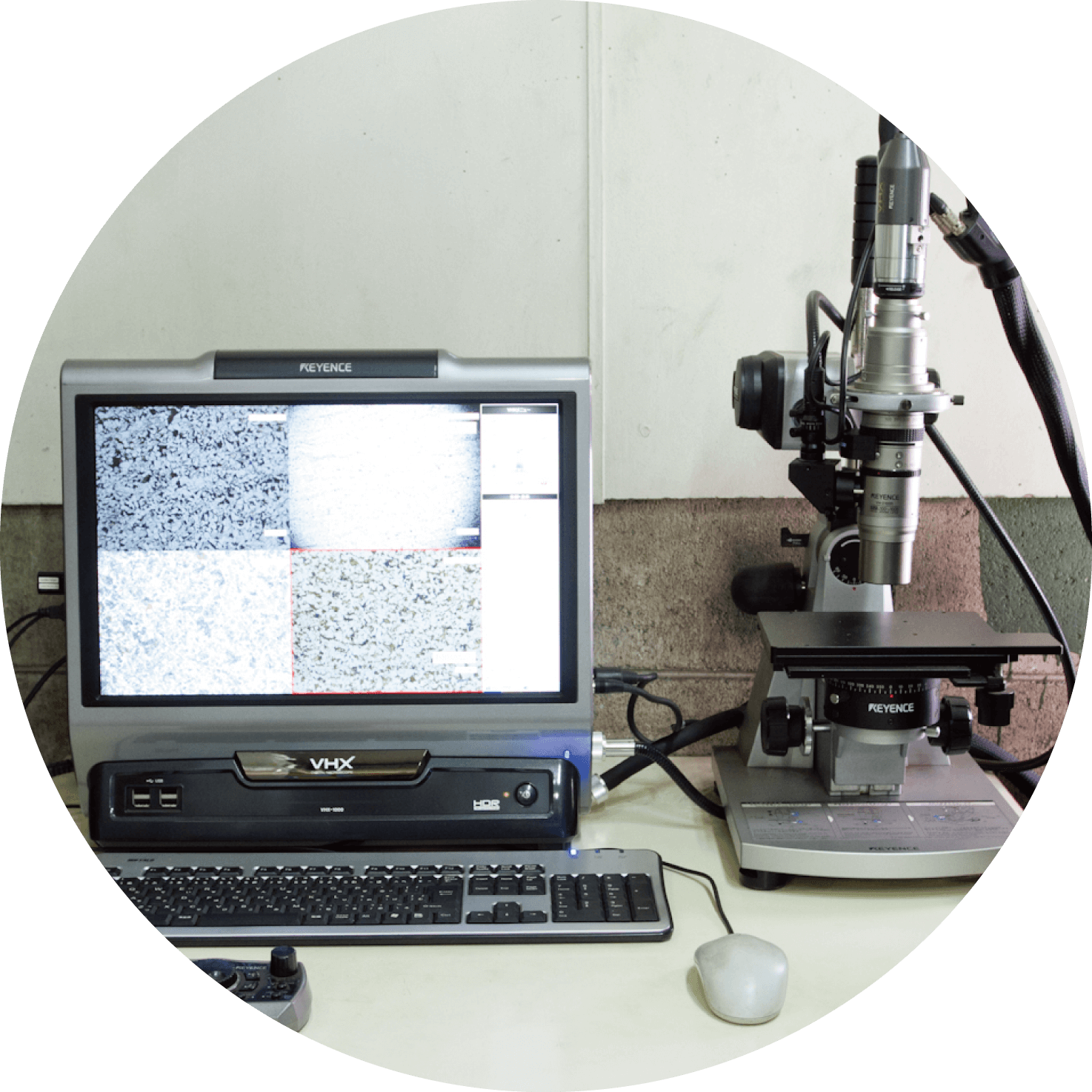

Microscope

We check materials’ structure by examining their microstructure. -

Contact Type Coordinate Measuring Machine

We also guarantee the geometric tolerance of the finished product with a CMM.

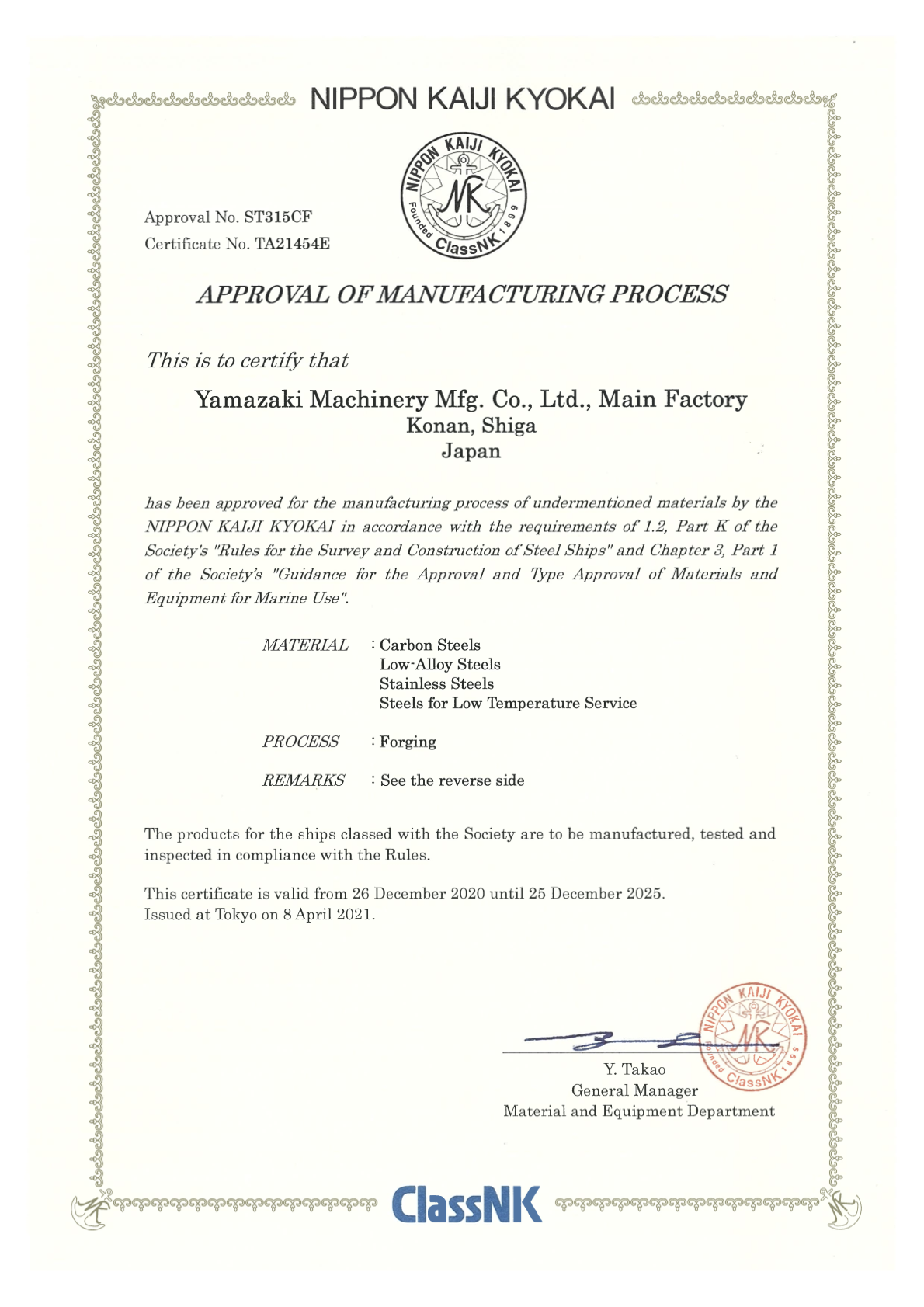

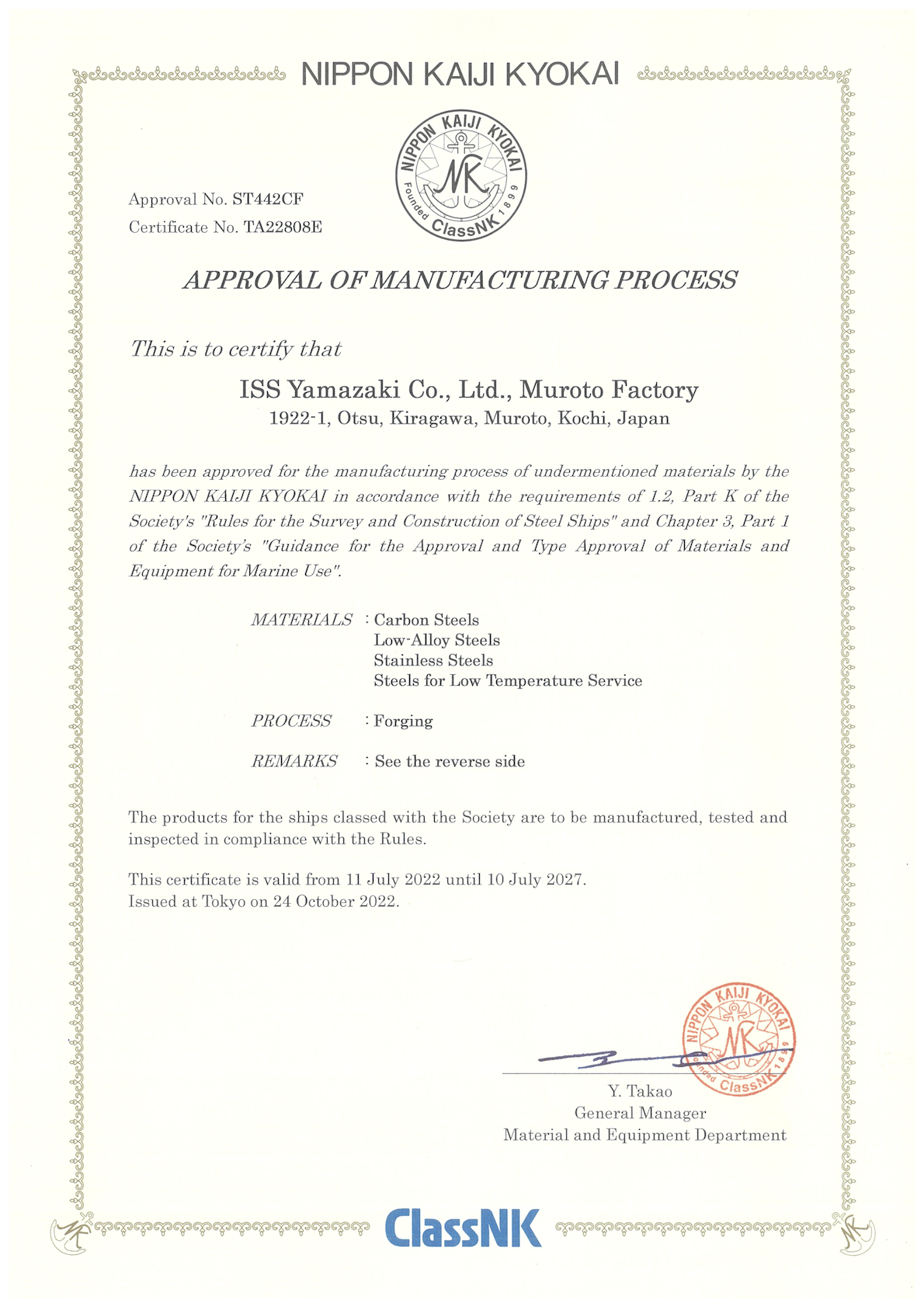

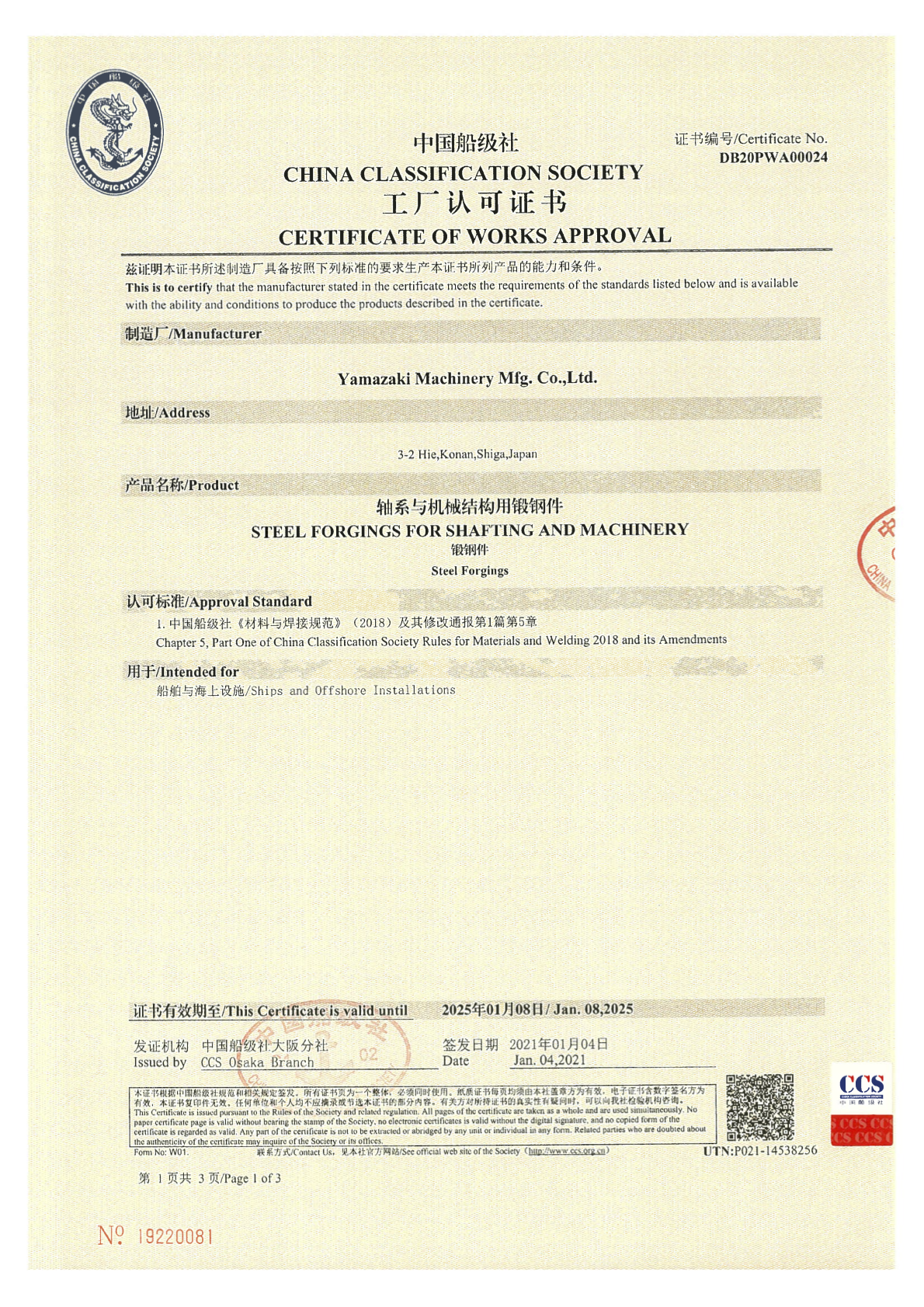

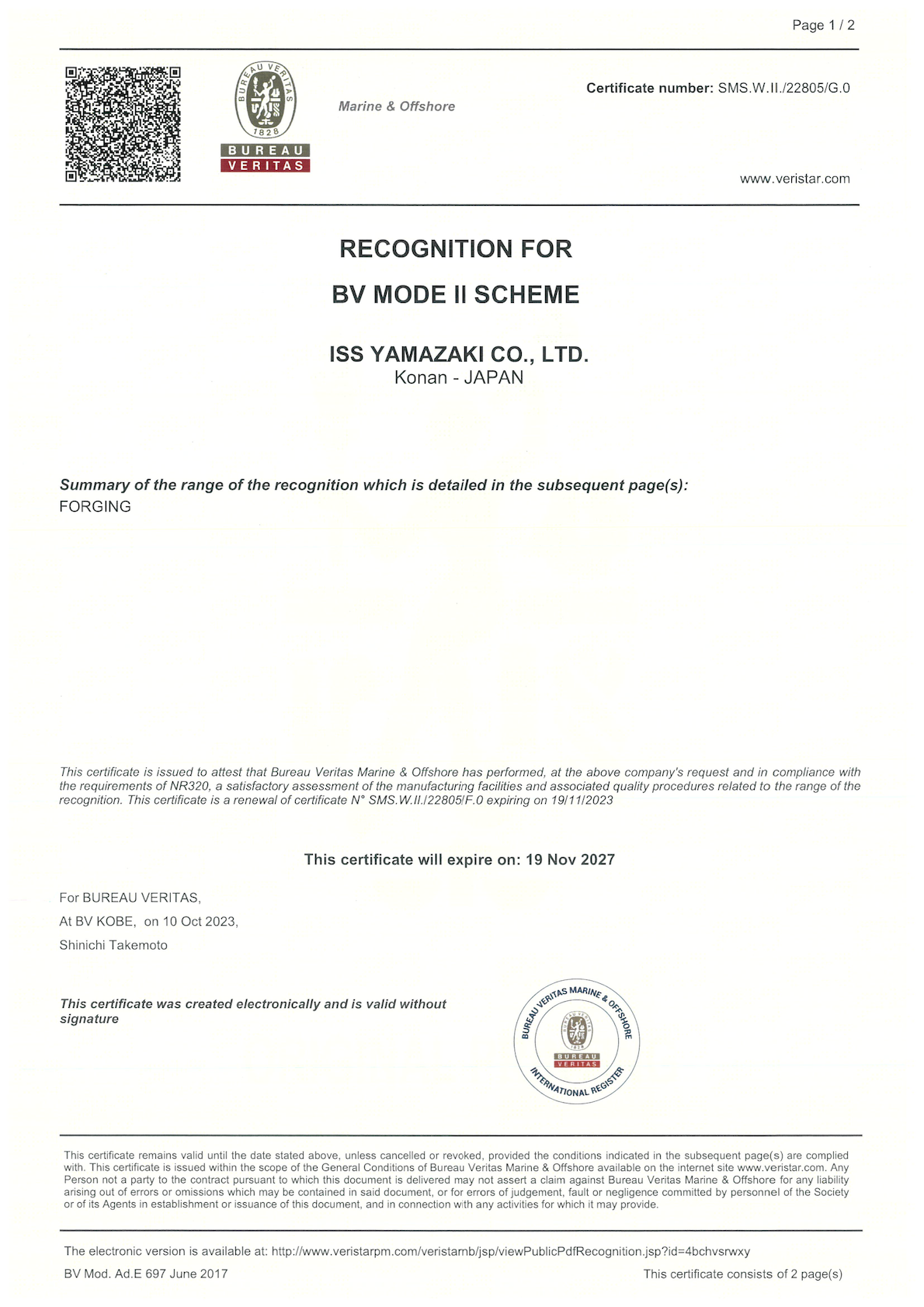

Certifications

ISS Yamazaki is certified by classification societies, which is indispensable for manufacturing and shipping marine parts, to meet the diverse needs of our customers. We hold various certifications necessary for dealing with customers in different industries.