Products

We Forge and Serve

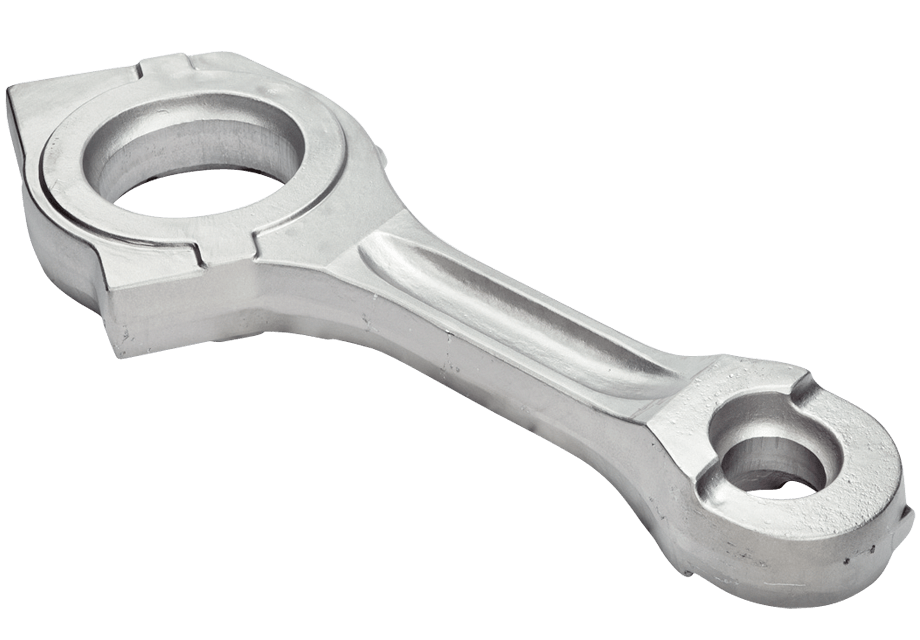

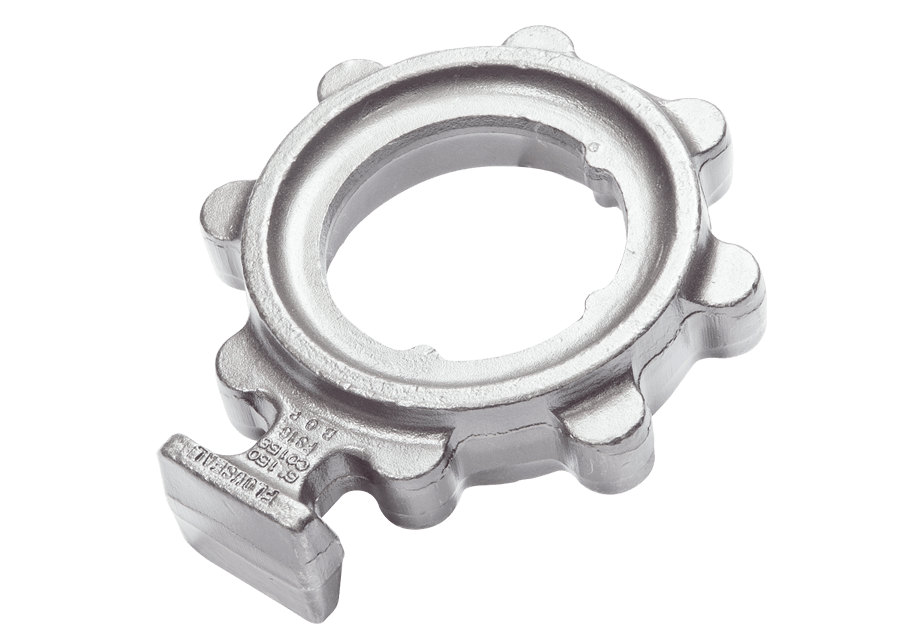

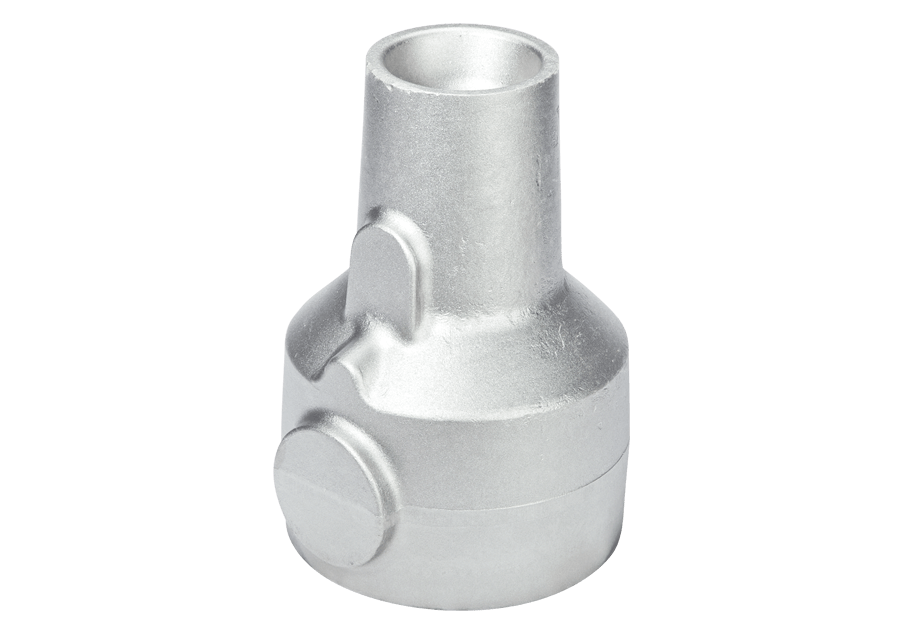

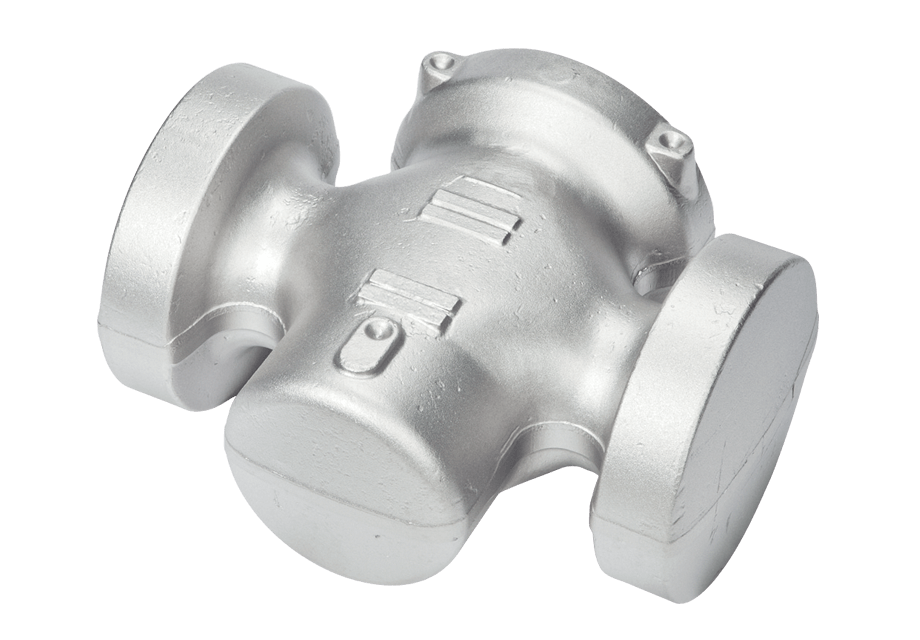

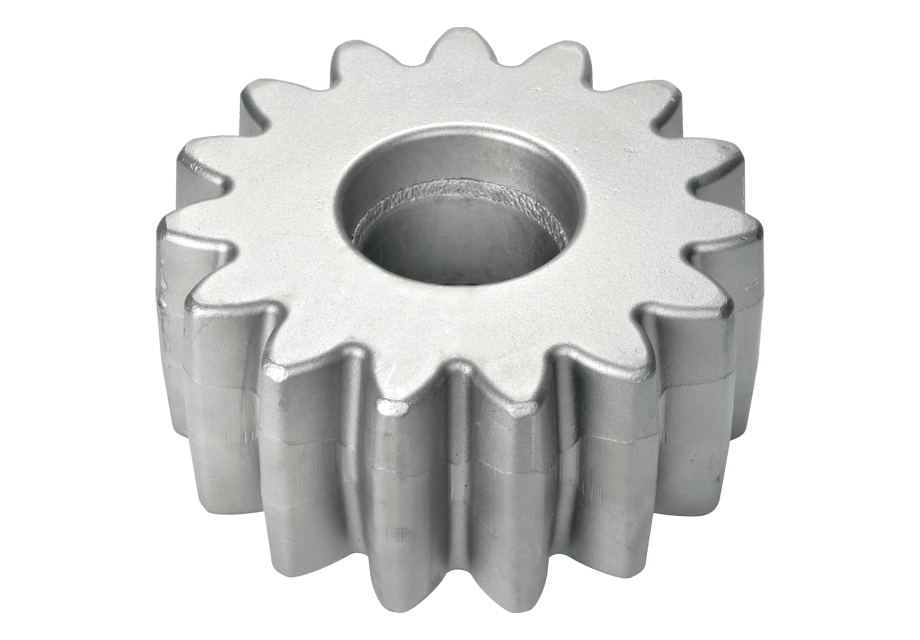

ISS Yamazaki’s die forging products are used in diverse fields such as construction machinery, ships, railroad cars, and building components.

Click the images for details.

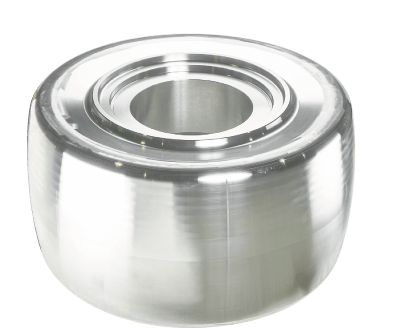

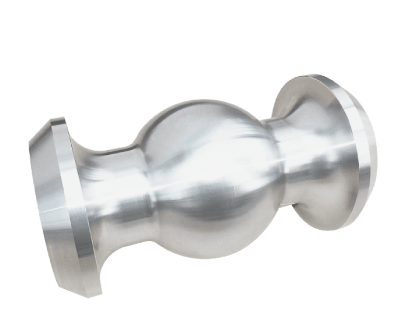

Finished Machining Products

-

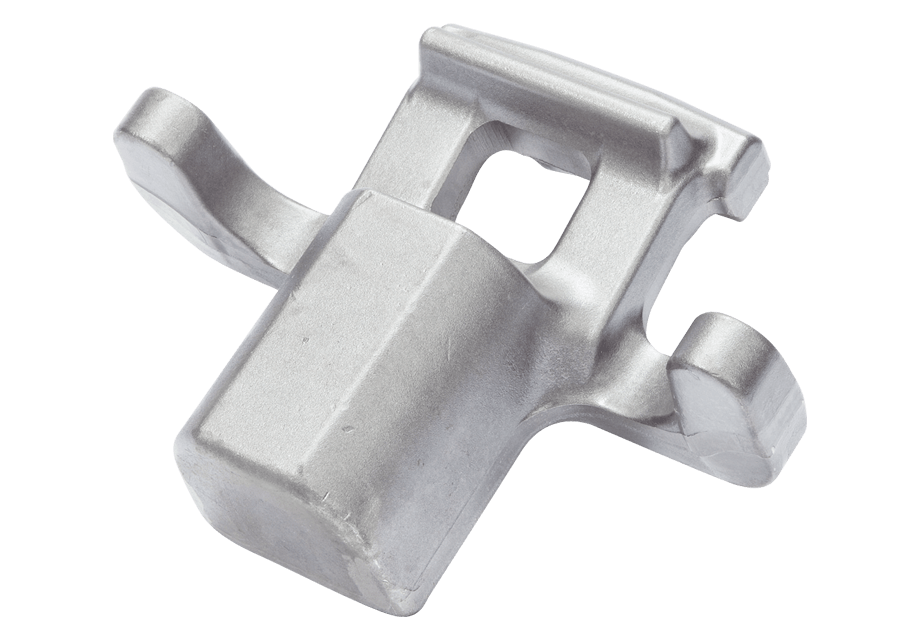

Construction Machinery Parts -

Bulldozer Parts -

Bulldozer Parts

Over 90% of our products are completed with finishing processes such as heat treatment and machining.

Cooperation with our group companies and various partner companies allows us to provide products tailored to the many different needs of our customers in terms of lot size, shape, material, specifications and so on. As our comprehensive production, including post-forging processes, are carried out in-house, low costs and short lead times under thorough quality control are realized.

Examples of Conversion

From Other Manufacturing Methods

to Die Forging

We promote die forging for metal products manufactured by many different methods, such as welding, casting, pressure welding, and lost-wax casting. We will devote our expertise that has been developed by our advantage in small-lot and high-mix production, based on our experiences over years.

-

From Open Die Forging to Die Forging

The biggest advantage of open die forging, which allows for roughly shaped finishes without dies, is manufacturing large products even for a single unit. On the other hand, its relatively large machining allowance and long machining time are disadvantages. ISS Yamazaki’s die forging has solved this problem with dies exclusively designed to be very close to the final shape. We have made it possible to die-forge the products that have been open-die-forged, utilizing our capability for forging over-1-ton products and small-lot production.

-

From Welding to Die Forging

We forge products that have been assembled by welding into a single unit. This eliminates the welding process and the instability of the strength of the welded parts. It also eliminates the reinforcing ribs typically required in welded products, allowing for smaller and lighter designs.

-

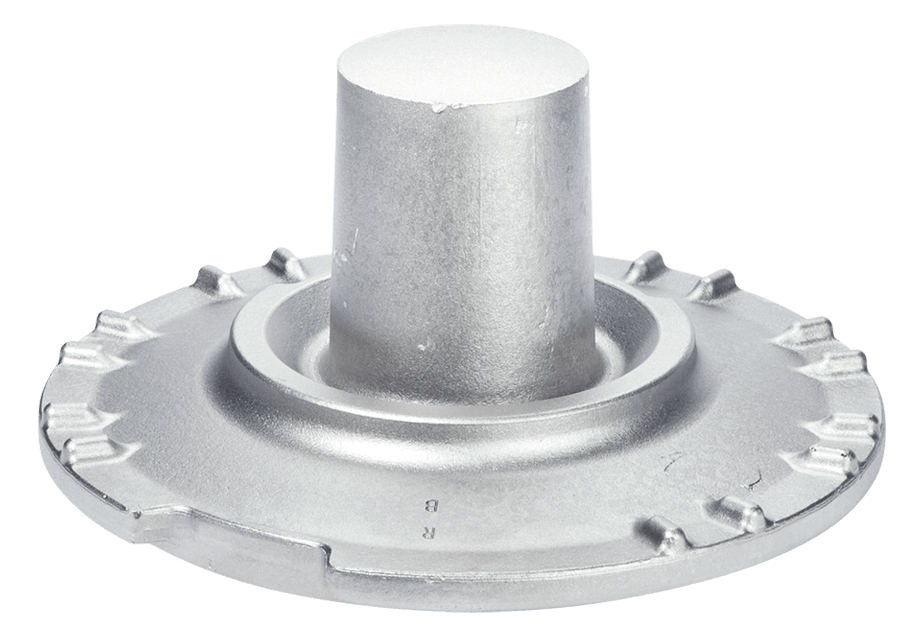

From Casting to Die Forging

As forged products are free from porosities, which is inevitable in casting, the labor and costs of repairs and remanufacturing can be avoided. In addition, metal structure flow (grain flow), which is absent in castings, enhance products’ strength. Therefore, they are often used in critical parts of construction machinery, railroad cars, and marine engines that particularly require strength and high quality.